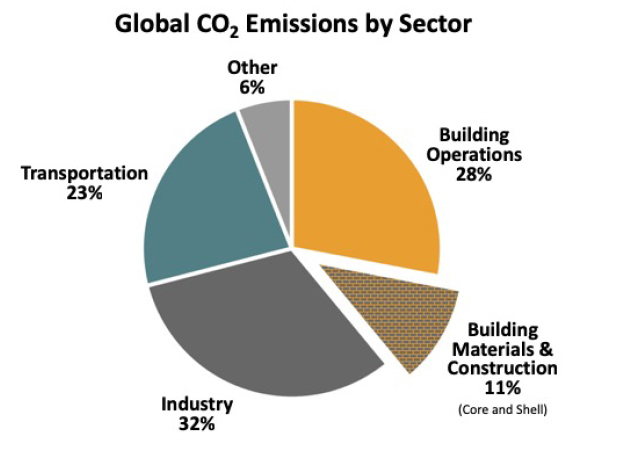

The materials which comprise a data center must have a circular nature, not be harmful to the environment, and simultaneously prolong the longevity of nature and human progress.

Rethinking and reusing environmental resources is not only good business but also a very important perspective for human welfare. Especially when considering the massive scale of resources used in the production of the materials for data center construction and the billions of dollars are spent in materials each year.

Sustainable materials that are friendly to both the environment and people can have a perpetual life of use to ensure we can scale data centers when needed and tackle climate change.”

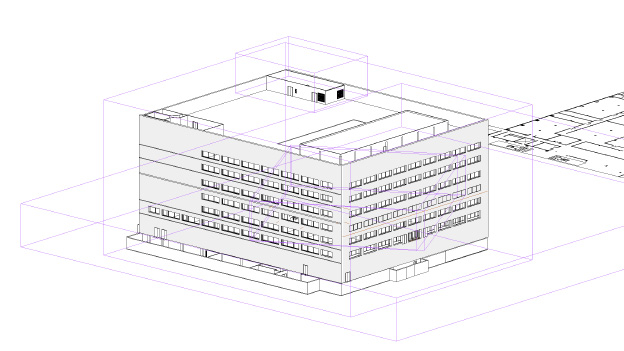

If we are to succeed with circular economics in the data center industry, we must deliberately depart from the linear practices, transition to circular thinking, and measure our progress. The circular economy approach must embrace end to end sustainability throughout the lifecycle for a data center (see illustration) and facilitate these changes for those who design, build, operate, and maintain them.

The cleanest data center is not powered by renewable energy, it is one that does not need to be built.

A circular economy enabled sustainable data center is designed for disassembly, each connection of the data center can be taken apart and each component can be refurbished, reused, recycled with zero waste and remake into a new material to give rise to a circular economic growth.

The combination of Sustainable Data Center design, 24x7x365 using carbon free energy, and triple zero (carbon, emissions, waste) delivers net zero to the carbon free pledge by data center sustainability leaders and effectively supports the UN SDG goals to tackle Climate Change.